Servicing ensures your robots are maintained to the highest standard to maximise production uptime and reduce the risk and cost of production downtime.

Servicing

Robot Preventative Maintenance

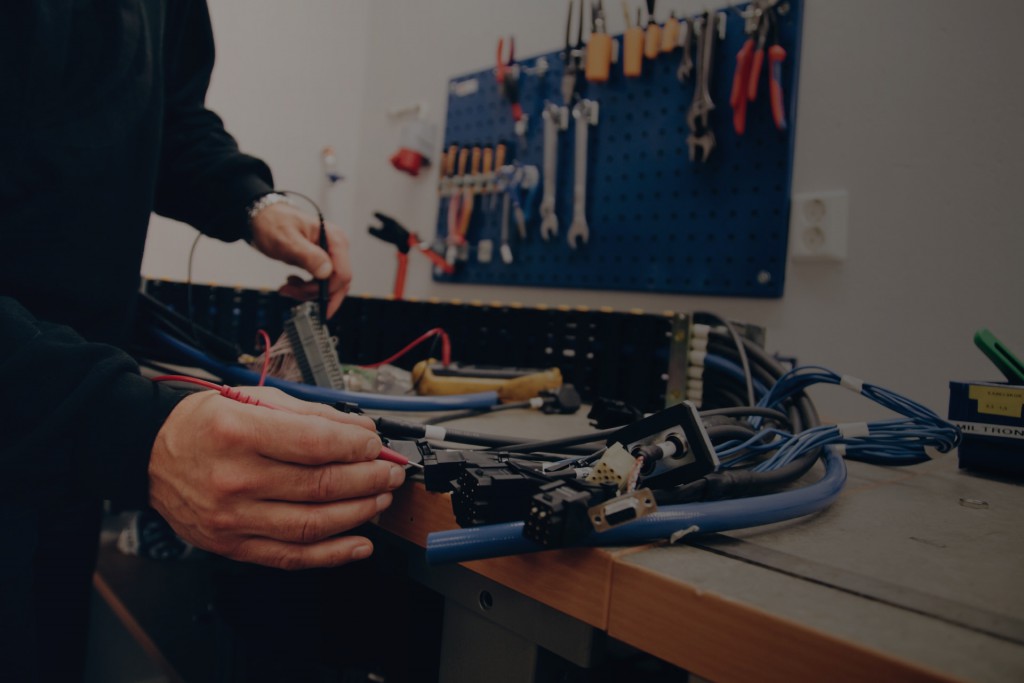

Preventative maintenance carried out by our dedicated PPM (Planned Preventative Maintenance) team at predetermined intervals is aimed at reducing the risk of robot failure.

During the regular maintenance visits, the team will inspect your robot and controller, complete regular maintenance activities (like greasing of mechanical parts, battery checks and software backups) and replace predefined parts.

Controller Evaluation

- Safety

- Lifecycle

- Clean and Vacuum Control Cabinet

- Replace filter if Applicable

- Check Cables and Connectors

- Test Teach Pendant Functionality

- Clean and Inspect Fan Units

- Complete Program Backups

- Software Version Check

- Check Memory Use

- Replace Controller Batteries if Applicable

Robot Maintenance

- Mechanical Sync / Calibration Check

- Conduct Motor Brake Slippage Test

- Axis Backlash / End Play Checks

- Check Over-travel Limits

- Check Lubrication

- Grease Mechanical Unit if Applicable

- Inspect Robot Cable Connections

- Replace Robot Batteries if Applicable

Additional Services

- External Axis / Track Service

- Oil and Grease Analysis

- Repeatability Checks

- Load and Tool weight indentification

Robot Health Check

RoboTeam offers a Robot Health Check, which is often used when a customer is purchasing a second hand or reconditioned robot to identify potential issues.

This empowers your investment by enabling purchase confidence or fair price negotiations.

RoboTeam service engineers undertake a 60 point visual inspection of the robot and controller and provide a report of their findings and recommendations.

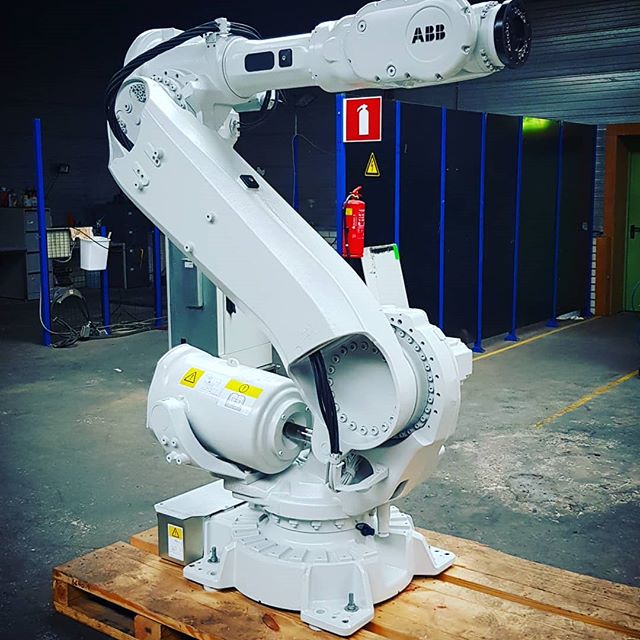

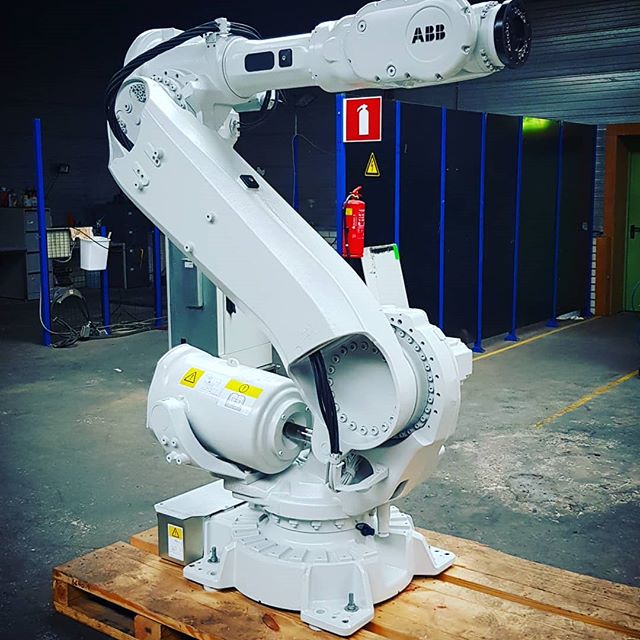

Robot Refurbishment and Reconditioning

We can also refurbish or recondition your existing robotic equipment at our workshop to extend the life of the robot.

Helping you to keep your existing robot installed base the same, whilst keeping the price down compared to a new robot.

We can also source and refurbish pre-owned robots for you.

Robot Lifecycle Assessment

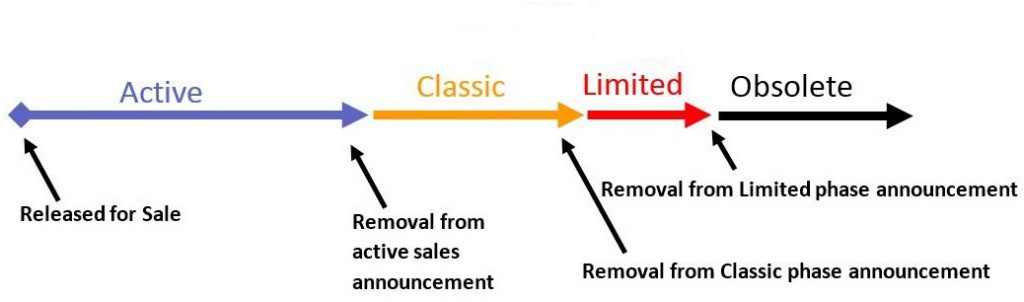

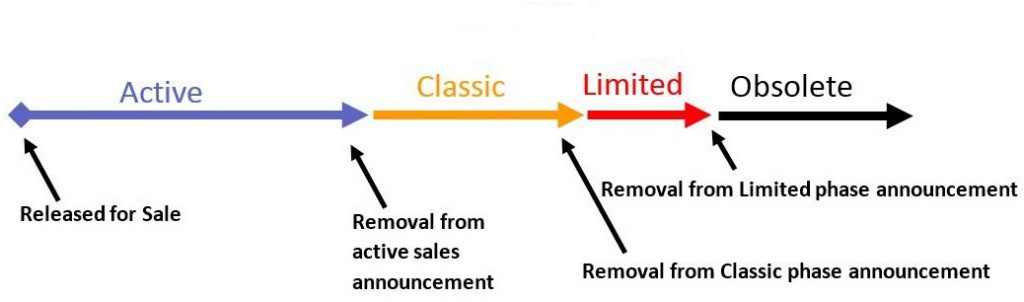

RoboTeam offer a Lifecycle Assessment for your robots, this capability enables you to future proof your productivity capability and plan your robotic automation upgrade or replacement investments.

The Lifecycle Assessment is undertaken by RoboTeam robotic service engineers to identify the current status of your robotic equipment.

The RoboTeam Lifecycle Assessment Report will provide expert recommendations to extend the life of your robotic equipment, maintenance that can be done and upgrade options.

An important feature of this service is the identification of issues regarding spare part obsolescence. This feature again enables your productivity future proofing. Your robot may be working well, but original robotic equipment manufacturers such as ABB, Fanuc, KUKA, Yaskawa/Motoman, Kawasaki, Naachi and Stäubli may no longer manufacture spares, if for example they released a newer robot model 10 years ago.

Comments are closed.